Supply Chain

Fuse Data and Forecasts to Reduce Risk and Sustain Operations

Readiness Challenge:

Supply Chain Management

Teams must anticipate and address operational sustainment, demand planning, and supply chain risks before issues arise—when every hour of downtime matters. It’s time to move beyond outdated statistical models and adopt proactive, explainable AI forecasting.

Organizations require interoperable AI solutions capable of fusing vast data sources and applying predictive analytics across complex supply chains. These solutions simulate, adapt, and respond in real time, generating the trust and agility needed to act decisively under pressure.

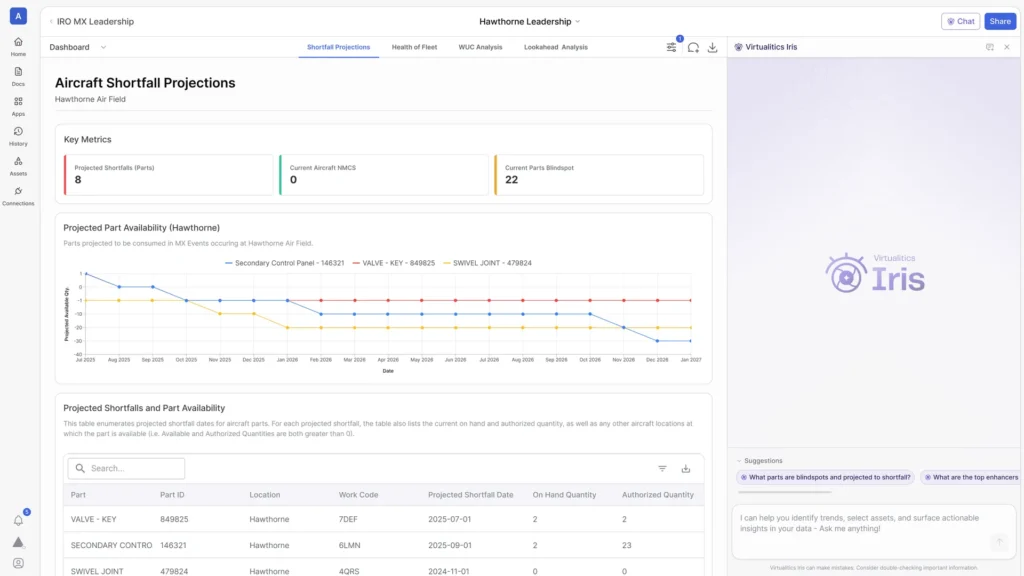

Powered by Virtualitics Integrated Readiness Optimization

AI Insights in IRO Reveal:

What gaps put the supply chain at risk?

Outsmart disruption. Quickly identify and quantify supply chain issues before operations are impacted.

How should we respond?

Optimize intelligently. Efficiently prioritize fixes, deliver key insights, and propose targeted alternatives.

What if?

Turn risk into readiness. Find solutions for all unanticipated supply chain challenges.

What customers are saying about IRO:

Ensure Supply Chain Stability and Efficiency

Key IRO features that support uptime:

Shortfall Projection

Determine when critical resources will become unavailable based on current or proposed planning.

Resource Constraint Analysis

Identify limiting factors across inventory based on current, scheduled, and predicted needs.

Operational Planning

Simulate strategies and surges in asset usage to determine impacts on operations and availability.

Parts Demand Projection

Anticipate critical resource needs in advance to ensure the necessary support is in place to maintain uptime and performance.

Deployed at Scale in the Mission Today

Time to Value

From data access to full-scale deployment

Awarded to Virtualitics

Our growing patent portfolio demonstrates our level of investment in AI innovation

IRO Deployments

Across all major military branches

Want to learn more? Let's chat.

Meet With Us