Maintenance

Empower Teams and Enhance Mission Reliability

Readiness Challenge:

Asset Maintenance

To remain at peak readiness, leaders need insight from varied sources on the health of their systems. Yet uncovering the connections between those sources is complex and time-consuming.

Holistic insight across parts, personnel, and equipment is critical for addressing challenges, increasing situational awareness, and improving operational readiness.

These challenges exist throughout a variety of critical and complex assets.

Aircraft

Ground Vehicles

Vessels

Drones

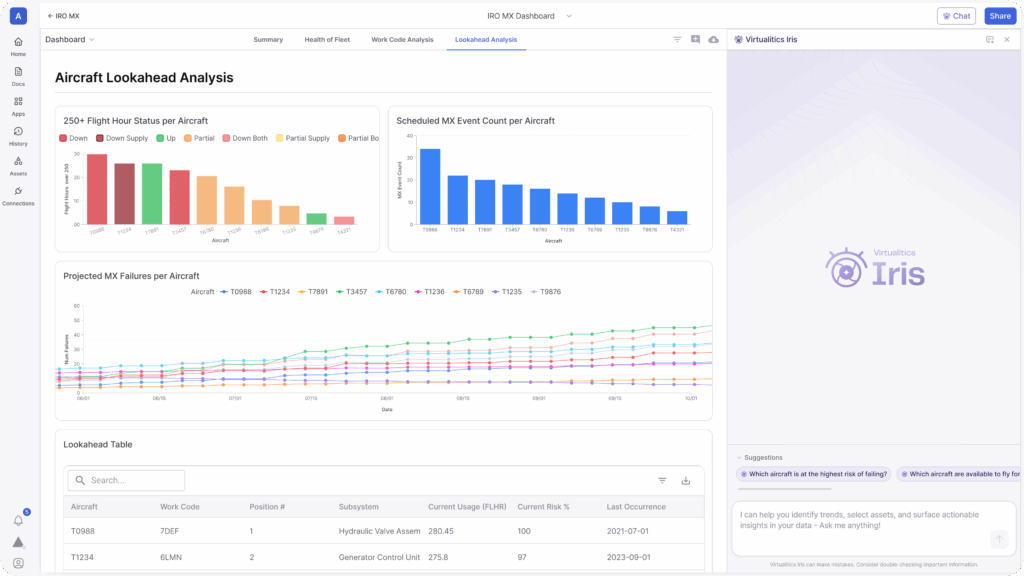

Powered by Virtualitics Integrated Readiness Optimization

AI Insights in IRO Reveal:

What assets are likely to fail?

Get ahead, stay ahead. Lookahead Analysis identifies components and assets at risk, predicting when failure is likely.

How should we respond?

Plan with precision. IRO provides a holistic view of resource, part, and equipment to optimize maintenance scheduling.

What if?

Stay mission capable. Be ready for anything, even when the unexpected occurs.

What customers are saying about IRO:

Avoid Operational Downtime and Maximize Mission Readiness

Key IRO features that impact operational readiness:

Asset Risk Assessment

Run machine learning survival analysis to determine when and why a component is going to fail.

Resource Constraint Analysis

Identify limiting factors across inventory, staffing, and repair equipment based on current, scheduled, and predicted needs.

Operational Planning

Simulate strategies and surges in asset usage to determine impacts on operations and availability.

Scheduling Optimization

Optimize maintenance schedules based on resource constraints, asset usage, and uptime requirements.

Deployed at Scale in the Mission Today

Time to Value

From data access to full-scale deployment

Awarded to Virtualitics

Our growing patent portfolio demonstrates our level of investment in AI innovation

IRO Deployments

Across all major military branches

Want to learn more?

Meet With Us